求一篇關(guān)于除塵器的外文及翻譯,要有標(biāo)題有出處。

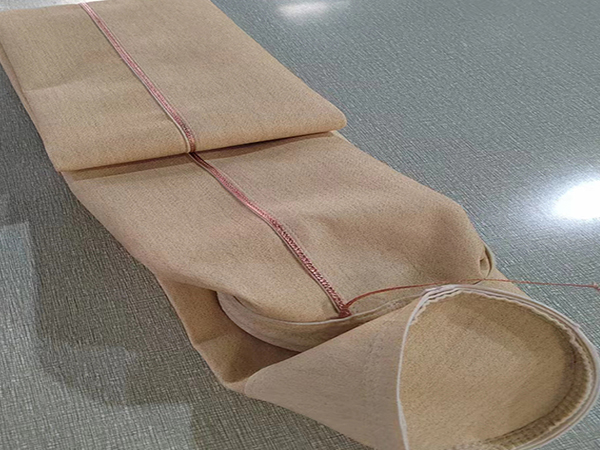

Bag dust collector, working mechanism is dusty smoke through the filter material, dust is filtered off, trapping coarse dust filter material mainly rely on the inertia collision, the capture of fine dust mainly by diffusion and the screening effect, the dust filter layer also has some filtering effect.

JDMC series pulse long bag dust collector Product Brief

The main factors affect the life of dust bag jam

JDMC series pulse long bag dust collector Product Brief

The main factors affect the life of dust bag jam

Expansion edit this section filter

Bag filter dust removal efficiency is related with many factors, but mainly dends on the filter. Bag filter dust collector is a synthetic fiber, natural fiber or glass fiber woven fabric or felt. According to the needs of the cloth or felt sewn into a cylinder or flat-shad bag. According to the flue gas prorties, select suitable application conditions of media. Usually, the teerature of the flue gas is lower than 120 DEG C, demand media with acid resistance and durability of the cases, often choose ester cloth and ester needled felt; in dealing with high teerature fume(< 250 degrees C), mainly uses the graphitization of glass cloth; in some scial cases, selection of carbon fiber and other media. In need of coal stone condition also need explosion proof antistatic treatment, the dust bag bag must choose the static-free silk fabric.

Pulse bag dust collector of single( 2) oration of bag dust filter in the control of flue gas through the filter sed( called the filtration sed) is very iortant. General admission filter sed is 0.5 2m/ min, for more than 0.1&181; m particulate efficiency can reach more than 99%, equipment resistance loss of aoximately 980- I470Pa.

Editor this paragraph of JDMC series pulse long bag dust collector

Bag dust collector is subdivided into more variety, today I will introduce a kind of

JDMC series pulse long bag dust collector is the coany engineering and technical rsonnel in the injection pulse( jet pulse) except for bag dust collector

Based on the technology of dust, and to meet the wind volume of flue gas purification needs of low pressure pulse bag dust collector. It has not only than the sail cloth bag dust remover deashing ability, high dust removal efficiency, emission concentration is low, but also has stable and reliable, low gas consution, covers an area of small features, particularly suitable for processing large amount of flue gas. JDMC series low-voltage long bag pulse filter in the world has been widely used, in foreign countries also has a large number of use, promotion, and can be widely used in cement, metallurgy, rochemical, building materials, food, machinery, electric power, carbon black, garbage, industrial furnace high teerature dust gas purification and dust-shad materials recovery. This product is integrated sectional reverse blow and pulse cleaning dust remover has the advantages of two ty, overcame sectional reverse blow ash strength is insufficient and the general pulse cleaning dust attached such shortcomings, the cleaning efficiency, injection frequency is greatly reduced. The use of the product drowned pulse valve, reducing the blowing air pressure and energy consution of equipment in oration, prolongs the service life of the valve bag filter, pulse, corehensive technical rformance in iroving.

The novel design, the air intake structure, coarse particles of a high teerature falls into the ash hopr directly, effectively protects the filter bag. Use of long bag, under the same processing power equipment covers an area of small, more convenient for the transformation of the old factory. Use divided chamber off-line cleaning, high efficiency, two times less dust adsorption, and effectively reducing the energy consution of the equipment, the filter bag with a pulse valve fatigue degree is reduced accordingly, increase the filter and valve life, reduce the number of equipment oration and maintenance costs. The maintenance for bag can not stop system fan, the normal oration of the system under the conditions of divided chamber. The bag mouth adopts a spring tensioning structure, convenient disassembly and assembly, good sealing rformance. The box body through the gas tightness design, and kerosene leak detection, maximum extent possible to reduce air leakage. The whole device by the PLC machine control, automatic cleaning, unloading, automatic teerature control and teerature n. There are many include a variety of dust removal equipment please visit

Editor this paragraph the main factors affect the life

Effects of dust bag using the main factors of service life of the bag is prolonged life matters needing attention

The bag is blocked, so that the resistance can be increased, by the differential pressure gauge readings increased rformance. The bag plug is caused by wear, rforation, bag off phenomenon. The cause of blockage caused by dust bag, press table check and repair. General to take the following measures 1 teorarily the dust bag, in order to eliminate clogging; partial or total recement of the bag; the adjustment of the mounting and orating conditions. To prevent dust bag plugging measures

The phenomenon of examination contents and measures

Wet dust collector bag box section water leakage eliminating water leakage, drying, reated cleaning

Dust da identifying causes of elimination of causes, repair

Bag insufficient tension adjustment, repair method of hanging

Identifying the causes of lower blocking bag adjustment, repair

Bag mounting bad installation method adjustment, repair

Ash cleaning in 1, hopr is sealed

In 2, the cleaning mechanism of fault

In 3, the reverse blowing volume

In 4, a spray pressure of insufficient adjustment, repair

Identifying the cause of change of bag bag contraction

Filtration rate too high air volume adjustment

Bag sha and bag installation method and mechanism determines the bag easily damaged position, and can check and repair. But mainly consists of the following causes bag breakage, such as occurrence breakage phenomenon can refer to the following table are examined Reason Reasons measures

Dust cleaning cycle is too long to adjust, shorten the aging identification and elimination of the causes

Cleaning time adjustment, shorten the bag because of heat hardens the identification and elimination of the causes

Insufficient tension adjustment, strengthen burn bag to study bag material

The bag is too slack adjustment leakage dust identification and elimination of the causes

Bag mounting bad adjustment, strengthening high filter sed adjustment to reduce

Mainly because of the following reasons caused by, be cause investigation, take measures to eliminate and rece the filter bag. 1, because of abnormal high teerature and hardening contraction; 2, with acid, alkali or organic solvent vapor exposure response; 3, and water reaction. 4, filter cloth is hung too loose or too tight, too easy to dust, too easy to pull bad. In 5, the new technology of old bags should not be mixed, to avoid damaging the time different effects of dust removal equipment normal work. 6, rece the bag, first with coressed air blowing net, and then check whether the holes, holes for recement after repair. As dust covered cloth bag, water washing, drying for recement.

布袋除塵器,工作機(jī)理是含塵煙氣通過(guò)過(guò)濾材料,塵粒被過(guò)濾下來(lái),過(guò)濾材料捕集粗粒粉塵主要靠慣碰撞作用,捕集細(xì)粒粉塵主要靠擴(kuò)散和篩分作用,濾料的粉塵層也有一定的過(guò)濾作用。

JDMC系列脈沖長(zhǎng)布袋除塵器產(chǎn)品簡(jiǎn)介

影響壽命的主要因素除塵布袋的堵塞

JDMC系列脈沖長(zhǎng)布袋除塵器產(chǎn)品簡(jiǎn)介

影響壽命的主要因素除塵布袋的堵塞

布袋除塵器除塵效果的優(yōu)劣與多種因素有關(guān),但主要取決于濾料。布袋除塵器的濾料就是合成纖維、天然纖維或玻璃纖維織成的布或氈。根據(jù)需要再把布或氈縫成圓筒或扁平形濾袋。根據(jù)煙氣質(zhì),選擇出適合于應(yīng)用條件的濾料。通常,在煙氣溫度低于120℃,要求濾料具有耐酸和耐久的情況下,常選用滌綸和滌綸針刺氈;在處理高溫?zé)煔?<250℃)時(shí),主要選用石墨化玻璃絲布;在某些特殊情況下,選用炭素纖維濾料等。在需要煤鐵石工況下還需要防爆防靜電處理,那除塵布袋布袋就要選擇防靜電絲的濾料.

脈沖單機(jī)布袋除塵器冊(cè)(2張)布袋除塵器運(yùn)行中控制煙氣通過(guò)濾料的速度(稱為過(guò)濾速度)頗為重要。一般取過(guò)濾速度為0.5—2m/min,對(duì)于大于0.1&181;m的微粒效率可達(dá)99%以上,設(shè)備阻力損失約為980—I470Pa。

編輯本段JDMC系列脈沖長(zhǎng)布袋除塵器

JDMC系列脈沖長(zhǎng)布袋除塵器是該工程技術(shù)人員在噴吹脈沖( jet pulse)除布袋除塵器

塵技術(shù)的基礎(chǔ)上,并為滿足大風(fēng)量煙氣凈化需要而研制的低壓脈沖袋除塵器。它不但具有比袋除塵器的清灰能力強(qiáng)、除塵效率高、排放濃度低等優(yōu)點(diǎn),還具有穩(wěn)定可靠、耗氣量低、占地面積小的特點(diǎn),特別適合處理大風(fēng)量煙氣.JDMC系列低壓長(zhǎng)袋脈沖除塵器已在世界范圍內(nèi)得到廣泛應(yīng)用,在國(guó)外也已大量使用、推廣,可廣泛應(yīng)用于水泥、冶金、石化、建材、糧食、機(jī)械、碳黑、電力、垃圾焚燒、工業(yè)窯爐等常溫或高溫含塵氣體的凈化及粉塵狀物料的。該產(chǎn)品綜合了分室反吹和脈沖清灰兩類除塵器的優(yōu)點(diǎn),克服了分室反吹清灰強(qiáng)度不足和一般脈沖清灰粉塵再附等缺點(diǎn),使清灰效率提高,噴吹頻率大為降低。該產(chǎn)品使用淹沒(méi)式脈沖閥,降低了噴吹氣源壓力和設(shè)備運(yùn)行能耗,延長(zhǎng)了濾袋、脈沖閥的使用壽命,綜合技術(shù)能大在提高。

●設(shè)計(jì)新穎,采用了進(jìn)氣結(jié)構(gòu),較粗的高溫顆粒直接落入灰斗,有效的保護(hù)了濾袋。●采用長(zhǎng)濾袋,在同等處理能力時(shí)設(shè)備占地面積少,更便于老廠改造。●采用分室分離線清灰,效率高,粉塵的二次吸附少,同時(shí)有效的降低了設(shè)備能耗,濾袋與脈沖閥的疲勞程度也相應(yīng)降低,成倍地提高了濾袋和閥片的壽命,大量減少了設(shè)備運(yùn)行維護(hù)的。●檢修換袋可在不停系統(tǒng)風(fēng)機(jī),系統(tǒng)正常運(yùn)行的條件下分室進(jìn)行。●濾袋袋口采用彈簧漲緊結(jié)構(gòu),拆裝方便,具有良好的密封。●箱體經(jīng)過(guò)氣密設(shè)計(jì),并以煤油檢漏,大程度上減少漏風(fēng)。●整臺(tái)設(shè)備由 PLC機(jī)控制,實(shí)現(xiàn)自動(dòng)清灰、卸灰、自動(dòng)溫度控制及超溫報(bào)幕。還有很多包括各種除塵器除塵設(shè)備請(qǐng)?jiān)L問(wèn):

影響除塵布袋使用壽命的主要因素延長(zhǎng)布袋壽命的注意事項(xiàng):

布袋發(fā)生堵塞時(shí),使阻力增高,可由壓差計(jì)的讀數(shù)增大表現(xiàn)出來(lái)。布袋堵塞是引起布袋磨損、穿孔、脫落等現(xiàn)象的主要原因。引起除塵布袋堵塞的原因,按下表進(jìn)行檢查并維修。一般采取下列措施:①暫時(shí)地加強(qiáng)清灰,以消除布袋的堵塞;②部分或全部更換布袋;③調(diào)整安裝和運(yùn)行條件。防止除塵布袋堵塞的措施

布袋淋濕除塵器箱體等部分漏水消除漏水、干燥、反復(fù)清灰

粉塵潮濕查明原因消除根源、維修

布袋張力不足懸掛方法調(diào)整、維修

布袋下部堵塞查明原因調(diào)整、維修

布袋安裝不良安裝方法調(diào)整、維修

布袋的形狀和布袋的安裝方法與機(jī)構(gòu)決定布袋容易破損的位置,依此可以進(jìn)行檢查和維修。但主要由下列原因引起布袋破損,如發(fā)生破損現(xiàn)象可參考下表進(jìn)行檢查:原因措施原因措施

清灰周期過(guò)長(zhǎng)調(diào)整、縮短濾袋老化查明并消除原因

清灰時(shí)間過(guò)長(zhǎng)調(diào)整、縮短濾袋因熱變硬查明并消除原因

布袋張力不足調(diào)整、加強(qiáng)燒毀重新研究濾袋材料

布袋過(guò)于松弛調(diào)整漏泄粉塵查明并消除原因

布袋安裝不良調(diào)整、加固濾速過(guò)高調(diào)整減小

主要由于以下原因引起的,須進(jìn)行原因調(diào)查,采取消除措施并更換除塵濾袋。 1、因異常高溫而硬化收縮; 2、因與酸、堿或有機(jī)溶劑的蒸氣接觸反應(yīng); 3、與水分發(fā)生反應(yīng)。 4、濾布不宜掛得過(guò)松或過(guò)緊,過(guò)松容易積塵,過(guò)緊容易拉壞。 5、新工藝舊布袋不應(yīng)混裝,避免損壞時(shí)間不同影響除塵設(shè)備正常工作。 6、更換下來(lái)的布袋,先用壓縮空氣吹凈,再檢查有無(wú)破洞,有破洞修好后留待更換。如被粉塵糊住的布袋,用水沖洗,涼干后留待更換。

求一篇袋式除塵器的外文及其翻譯,大神們救命啊!!!

Bag dust collector, working mechanism is dusty smoke through the filter material, dust is filtered off, trapping coarse dust filter material mainly rely on the inertia collision, the capture of fine dust mainly by diffusion and the screening effect, the dust filter layer also has some filtering effect.

JDMC series pulse long bag dust collector Product Brief

The main factors affect the life of dust bag jam

JDMC series pulse long bag dust collector Product Brief

The main factors affect the life of dust bag jam

Expansion edit this section filter

Bag filter dust removal efficiency is related with many factors, but mainly dends on the filter. Bag filter dust collector is a synthetic fiber, natural fiber or glass fiber woven fabric or felt. According to the needs of the cloth or felt sewn into a cylinder or flat-shad bag. According to the flue gas prorties, select suitable application conditions of media. Usually, the teerature of the flue gas is lower than 120 DEG C, demand media with acid resistance and durability of the cases, often choose ester cloth and ester needled felt; in dealing with high teerature fume(< 250 degrees C), mainly uses the graphitization of glass cloth; in some scial cases, selection of carbon fiber and other media. In need of coal stone condition also need explosion proof antistatic treatment, the dust bag bag must choose the static-free silk fabric.

Pulse bag dust collector of single( 2) oration of bag dust filter in the control of flue gas through the filter sed( called the filtration sed) is very iortant. General admission filter sed is 0.5 2m/ min, for more than 0.1μ m particulate efficiency can reach more than 99%, equipment resistance loss of aoximately 980- I470Pa.

Editor this paragraph of JDMC series pulse long bag dust collector

Bag dust collector is subdivided into more variety, today I will introduce a kind of

JDMC series pulse long bag dust collector is the coany engineering and technical rsonnel in the injection pulse( jet pulse) except for bag dust collector

Based on the technology of dust, and to meet the wind volume of flue gas purification needs of low pressure pulse bag dust collector. It has not only than the sail cloth bag dust remover deashing ability, high dust removal efficiency, emission concentration is low, but also has stable and reliable, low gas consution, covers an area of small features, particularly suitable for processing large amount of flue gas. JDMC series low-voltage long bag pulse filter in the world has been widely used, in foreign countries also has a large number of use, promotion, and can be widely used in cement, metallurgy, rochemical, building materials, food, machinery, electric power, carbon black, garbage, industrial furnace high teerature dust gas purification and dust-shad materials recovery. This product is integrated sectional reverse blow and pulse cleaning dust remover has the advantages of two ty, overcame sectional reverse blow ash strength is insufficient and the general pulse cleaning dust attached such shortcomings, the cleaning efficiency, injection frequency is greatly reduced. The use of the product drowned pulse valve, reducing the blowing air pressure and energy consution of equipment in oration, prolongs the service life of the valve bag filter, pulse, corehensive technical rformance in iroving.

The novel design, the air intake structure, coarse particles of a high teerature falls into the ash hopr directly, effectively protects the filter bag. Use of long bag, under the same processing power equipment covers an area of small, more convenient for the transformation of the old factory. Use divided chamber off-line cleaning, high efficiency, two times less dust adsorption, and effectively reducing the energy consution of the equipment, the filter bag with a pulse valve fatigue degree is reduced accordingly, increase the filter and valve life, reduce the number of equipment oration and maintenance costs. The maintenance for bag can not stop system fan, the normal oration of the system under the conditions of divided chamber. The bag mouth adopts a spring tensioning structure, convenient disassembly and assembly, good sealing rformance. The box body through the gas tightness design, and kerosene leak detection, maximum extent possible to reduce air leakage. The whole device by the PLC machine control, automatic cleaning, unloading, automatic teerature control and teerature n. There are many include a variety of dust removal equipment please visit

Editor this paragraph the main factors affect the life

Effects of dust bag using the main factors of service life of the bag is prolonged life matters needing attention

The bag is blocked, so that the resistance can be increased, by the differential pressure gauge readings increased rformance. The bag plug is caused by wear, rforation, bag off phenomenon. The cause of blockage caused by dust bag, press table check and repair. General to take the following measures 1 teorarily the dust bag, in order to eliminate clogging; partial or total recement of the bag; the adjustment of the mounting and orating conditions. To prevent dust bag plugging measures

The phenomenon of examination contents and measures

Wet dust collector bag box section water leakage eliminating water leakage, drying, reated cleaning

Dust da identifying causes of elimination of causes, repair

Bag insufficient tension adjustment, repair method of hanging

Identifying the causes of lower blocking bag adjustment, repair

Bag mounting bad installation method adjustment, repair

Ash cleaning in 1, hopr is sealed

In 2, the cleaning mechanism of fault

In 3, the reverse blowing volume

In 4, a spray pressure of insufficient adjustment, repair

Identifying the cause of change of bag bag contraction

Filtration rate too high air volume adjustment

Bag sha and bag installation method and mechanism determines the bag easily damaged position, and can check and repair. But mainly consists of the following causes bag breakage, such as occurrence breakage phenomenon can refer to the following table are examined Reason Reasons measures

Dust cleaning cycle is too long to adjust, shorten the aging identification and elimination of the causes

Cleaning time adjustment, shorten the bag because of heat hardens the identification and elimination of the causes

Insufficient tension adjustment, strengthen burn bag to study bag material

The bag is too slack adjustment leakage dust identification and elimination of the causes

Bag mounting bad adjustment, strengthening high filter sed adjustment to reduce

Mainly because of the following reasons caused by, be cause investigation, take measures to eliminate and rece the filter bag. 1, because of abnormal high teerature and hardening contraction; 2, with acid, alkali or organic solvent vapor exposure response; 3, and water reaction. 4, filter cloth is hung too loose or too tight, too easy to dust, too easy to pull bad. In 5, the new technology of old bags should not be mixed, to avoid damaging the time different effects of dust removal equipment normal work. 6, rece the bag, first with coressed air blowing net, and then check whether the holes, holes for recement after repair. As dust covered cloth bag, water washing, drying for recement.

布袋除塵器,工作機(jī)理是含塵煙氣通過(guò)過(guò)濾材料,塵粒被過(guò)濾下來(lái),過(guò)濾材料捕集粗粒粉塵主要靠慣碰撞作用,捕集細(xì)粒粉塵主要靠擴(kuò)散和篩分作用,濾料的粉塵層也有一定的過(guò)濾作用。

JDMC系列脈沖長(zhǎng)布袋除塵器產(chǎn)品簡(jiǎn)介

影響壽命的主要因素除塵布袋的堵塞

JDMC系列脈沖長(zhǎng)布袋除塵器產(chǎn)品簡(jiǎn)介

影響壽命的主要因素除塵布袋的堵塞

布袋除塵器除塵效果的優(yōu)劣與多種因素有關(guān),但主要取決于濾料。布袋除塵器的濾料就是合成纖維、天然纖維或玻璃纖維織成的布或氈。根據(jù)需要再把布或氈縫成圓筒或扁平形濾袋。根據(jù)煙氣質(zhì),選擇出適合于應(yīng)用條件的濾料。通常,在煙氣溫度低于120℃,要求濾料具有耐酸和耐久的情況下,常選用滌綸和滌綸針刺氈;在處理高溫?zé)煔?<250℃)時(shí),主要選用石墨化玻璃絲布;在某些特殊情況下,選用炭素纖維濾料等。在需要煤鐵石工況下還需要防爆防靜電處理,那除塵布袋布袋就要選擇防靜電絲的濾料.

脈沖單機(jī)布袋除塵器冊(cè)(2張)布袋除塵器運(yùn)行中控制煙氣通過(guò)濾料的速度(稱為過(guò)濾速度)頗為重要。一般取過(guò)濾速度為0.5—2m/min,對(duì)于大于0.1μm的微粒效率可達(dá)99%以上,設(shè)備阻力損失約為980—I470Pa。

編輯本段JDMC系列脈沖長(zhǎng)布袋除塵器

JDMC系列脈沖長(zhǎng)布袋除塵器是該工程技術(shù)人員在噴吹脈沖( jet pulse)除布袋除塵器

塵技術(shù)的基礎(chǔ)上,并為滿足大風(fēng)量煙氣凈化需要而研制的低壓脈沖袋除塵器。它不但具有比袋除塵器的清灰能力強(qiáng)、除塵效率高、排放濃度低等優(yōu)點(diǎn),還具有穩(wěn)定可靠、耗氣量低、占地面積小的特點(diǎn),特別適合處理大風(fēng)量煙氣.JDMC系列低壓長(zhǎng)袋脈沖除塵器已在世界范圍內(nèi)得到廣泛應(yīng)用,在國(guó)外也已大量使用、推廣,可廣泛應(yīng)用于水泥、冶金、石化、建材、糧食、機(jī)械、碳黑、電力、垃圾焚燒、工業(yè)窯爐等常溫或高溫含塵氣體的凈化及粉塵狀物料的。該產(chǎn)品綜合了分室反吹和脈沖清灰兩類除塵器的優(yōu)點(diǎn),克服了分室反吹清灰強(qiáng)度不足和一般脈沖清灰粉塵再附等缺點(diǎn),使清灰效率提高,噴吹頻率大為降低。該產(chǎn)品使用淹沒(méi)式脈沖閥,降低了噴吹氣源壓力和設(shè)備運(yùn)行能耗,延長(zhǎng)了濾袋、脈沖閥的使用壽命,綜合技術(shù)能大在提高。

●設(shè)計(jì)新穎,采用了進(jìn)氣結(jié)構(gòu),較粗的高溫顆粒直接落入灰斗,有效的保護(hù)了濾袋。●采用長(zhǎng)濾袋,在同等處理能力時(shí)設(shè)備占地面積少,更便于老廠改造。●采用分室分離線清灰,效率高,粉塵的二次吸附少,同時(shí)有效的降低了設(shè)備能耗,濾袋與脈沖閥的疲勞程度也相應(yīng)降低,成倍地提高了濾袋和閥片的壽命,大量減少了設(shè)備運(yùn)行維護(hù)的。●檢修換袋可在不停系統(tǒng)風(fēng)機(jī),系統(tǒng)正常運(yùn)行的條件下分室進(jìn)行。●濾袋袋口采用彈簧漲緊結(jié)構(gòu),拆裝方便,具有良好的密封。●箱體經(jīng)過(guò)氣密設(shè)計(jì),并以煤油檢漏,大程度上減少漏風(fēng)。●整臺(tái)設(shè)備由 PLC機(jī)控制,實(shí)現(xiàn)自動(dòng)清灰、卸灰、自動(dòng)溫度控制及超溫報(bào)幕。還有很多包括各種除塵器除塵設(shè)備請(qǐng)?jiān)L問(wèn):

影響除塵布袋使用壽命的主要因素延長(zhǎng)布袋壽命的注意事項(xiàng):

布袋發(fā)生堵塞時(shí),使阻力增高,可由壓差計(jì)的讀數(shù)增大表現(xiàn)出來(lái)。布袋堵塞是引起布袋磨損、穿孔、脫落等現(xiàn)象的主要原因。引起除塵布袋堵塞的原因,按下表進(jìn)行檢查并維修。一般采取下列措施:①暫時(shí)地加強(qiáng)清灰,以消除布袋的堵塞;②部分或全部更換布袋;③調(diào)整安裝和運(yùn)行條件。防止除塵布袋堵塞的措施

布袋淋濕除塵器箱體等部分漏水消除漏水、干燥、反復(fù)清灰

粉塵潮濕查明原因消除根源、維修

布袋張力不足懸掛方法調(diào)整、維修

布袋下部堵塞查明原因調(diào)整、維修

布袋安裝不良安裝方法調(diào)整、維修

布袋的形狀和布袋的安裝方法與機(jī)構(gòu)決定布袋容易破損的位置,依此可以進(jìn)行檢查和維修。但主要由下列原因引起布袋破損,如發(fā)生破損現(xiàn)象可參考下表進(jìn)行檢查:原因措施原因措施

清灰周期過(guò)長(zhǎng)調(diào)整、縮短濾袋老化查明并消除原因

清灰時(shí)間過(guò)長(zhǎng)調(diào)整、縮短濾袋因熱變硬查明并消除原因

布袋張力不足調(diào)整、加強(qiáng)燒毀重新研究濾袋材料

布袋過(guò)于松弛調(diào)整漏泄粉塵查明并消除原因

布袋安裝不良調(diào)整、加固濾速過(guò)高調(diào)整減小

主要由于以下原因引起的,須進(jìn)行原因調(diào)查,采取消除措施并更換除塵濾袋。 1、因異常高溫而硬化收縮; 2、因與酸、堿或有機(jī)溶劑的蒸氣接觸反應(yīng); 3、與水分發(fā)生反應(yīng)。 4、濾布不宜掛得過(guò)松或過(guò)緊,過(guò)松容易積塵,過(guò)緊容易拉壞。 5、新工藝舊布袋不應(yīng)混裝,避免損壞時(shí)間不同影響除塵設(shè)備正常工作。 6、更換下來(lái)的布袋,先用壓縮空氣吹凈,再檢查有無(wú)破洞,有破洞修好后留待更換。如被粉塵糊住的布袋,用水沖洗,涼干后留待更換。

客服1

客服1  客服2

客服2